CSM Tech wins IMC Awards for transformation at JSW mines

Bhubaneswar, June 24: CSM Technologies, a Bhubaneswar-headquartered IT consulting firm with business footprint in USA, Dubai and Africa, has won the prestigious IMC Digital Technology Awards 2022 for Digital Logistics Management Solution (DLMS) in Category 1D- ‘Established IT and Technology Service companies transforming other businesses digitally across sectors’. DLMS has been implemented at JSW Steel’s Jajang, Gonua, Narayanposhi and Nuagaon mines of Odisha. The Multi-modal digital logistics management solution designed in sync with the Prime Minister’s Gati Shakti initiative, covers 13 railways sidings, 4 mines and 3 ports. The solution has enabled better production planning and pit-to-port optimization, bringing in gains like higher efficiency, enhanced transparency, lower Turnaround Time (TAT) and cost optimization with minimal human intervention. Ranjan Nayak COO of JSW Steel Odisha said, “In a quick changing mining landscape, automation of processes has become critical for seamless operations and transformative outcomes. IT in Logistics is one such ground breaking solution that has enabled our mines to balance process automation with higher productivity. The outcomes that we have achieved on ground after onboarding DLMS are a testimony to its efficacy”. “This award is a testimony to the transformative impact of logisticsin tackling the multi-modal transportation challenge in the mining value chain. CSM Tech got the opportunity to implement this seamless solution at JSW’s mines and script a transformation on key mining parameters on the ground”, said Priyadarshi Nanu Pany, Founder &CEO of CSM Technologies. The end-to-end mining logistics automation system has addressed problems like pilferage, untraceable material movement and porous/opaque movement of mineral carrying vehicles plying within the mining premises. The successful implementation of DLMS has reduced the time by 81% at critical touch points of dispatch trucks (In-Bound of the mines) and an average of only 3 hours less TAT (Turnaround Time) per permit. The reduced weighbridge operating cost and optimization of resources have enhanced the end-to-end performance of the mine-to-market value chain with increased productivity of 20%. The USPs of the integrated logistics systems are a centralized dashboard with drill-down capabilities for capturing heterogeneous data and a 360-degree view of the quantity of production, dispatch rate, and transporter's performance. Algorithms powered by Artificial Intelligence (AI) and Machine Learning (ML) enable miners to track every stage of the supply chain, minimize in-transit theft and ensure their product reaches the final touch point on time.

Latest News

Odisha driver Mahasangha supports Congress wor...

Fire breaks out at Rourkela Railway Station: B...

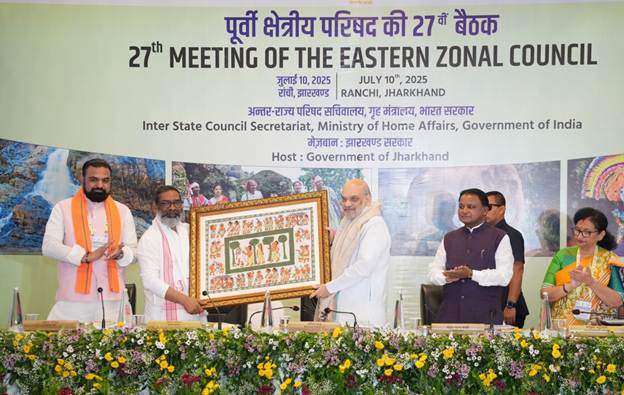

Amit Shah chairs 27th meeting of the Eastern Z...

Eastern Zonal Council Meeting with Amit Shah c...

Rahul Gandhi’s Odisha visit tomorrow: CP draws...

Kapil Sharma’s Kap’s Café in Canada attacked b...

Bhubaneswar first track court sentences man to...

Copyright © 2024 - Summa Real Media Private Limited. All Rights Reserved.